New production line boosts capacity & flexibility

We proudly announce the installation of a second production line, which enables the production of RoFoam XPE foam in rolls of >2 meter. The new line will be fully operational from mid-April onwards.

Foam Expo

Europe

From 11 to 13 November 2025, we participated in Foam Expo. We look back on a successful event and thank everyone who visited our stand for their time, feedback and interest in RoFoam.

Read more

RoFoam odor test

(VDA 270)

Odor matters as much as performance and safety in automotive interiors. That’s why RoFoam is tested according to the VDA 270 standard. Discover how our solutions ensure compliance with strict OEM criteria.

Quality assurance:

our test lab

At Schmitz Foam Supply, product reliability is a key priority. In our dedicated test lab, RoFoam undergoes a range of tests to ensure consistent performance under various conditions. Learn more about our testing approach.

Recycled material content in RoFoam

With foam products made partly from recycled raw materials and our innovative end-of-life foam recycling solution, we fully embrace sustainability and circularity across our entire production process.

Read more

In-house fire lab

We proudly present our state-of-the-art in-house fire laboratory for foam testing, enhancing product alignment with customer needs and standards.

Read more

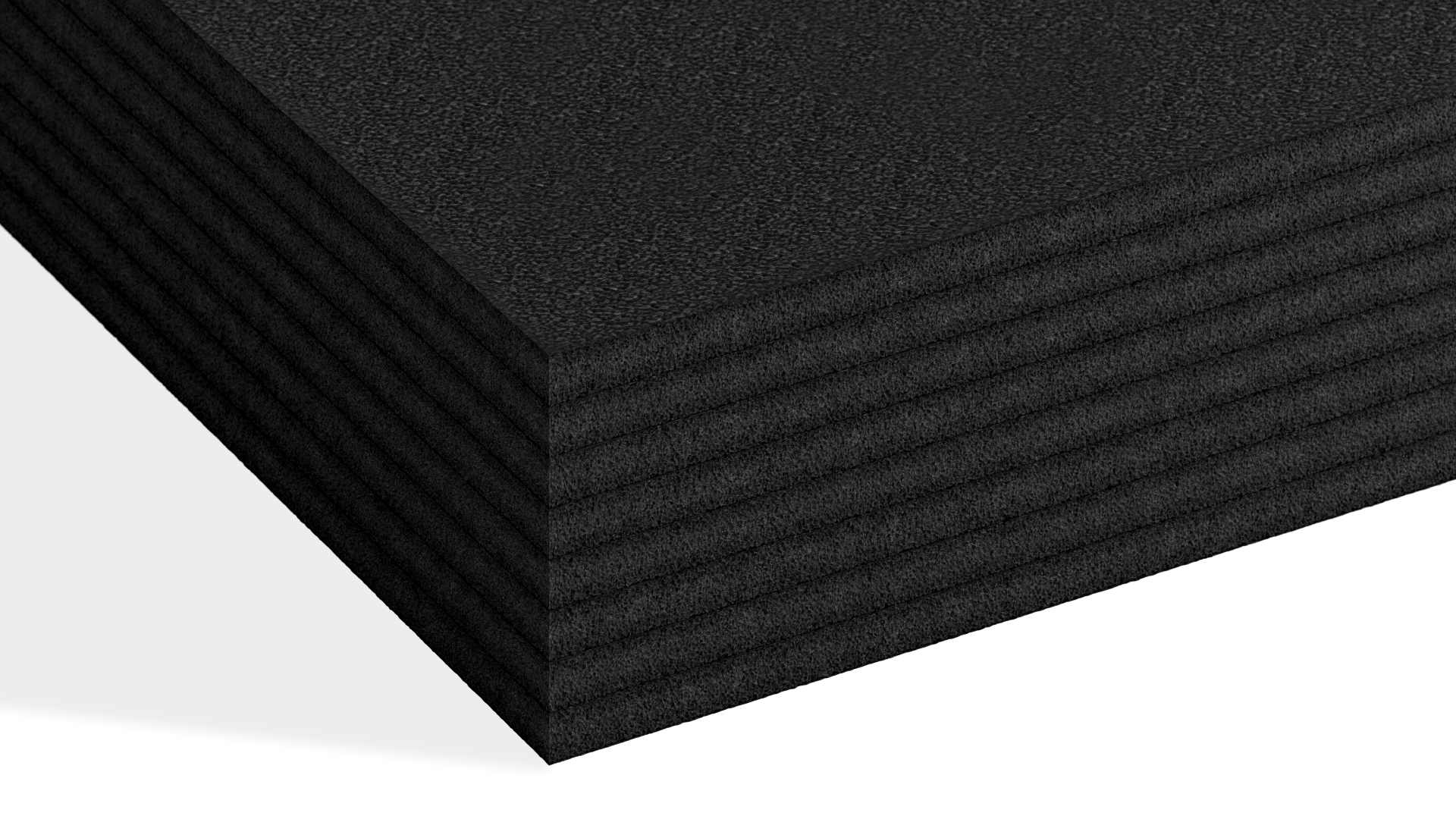

NEW:

RoFoam Block

Our crosslinked polyolefin RoFoam is now also available as laminated block foam. RoFoam Block is directly available from stock at a competitive price.

Read more

Zero Foam Waste

Have a look at the circular approach we employ when we collect foam residues. See how we transform foam scraps into a new raw material, which we then upcycle into high-quality and sustainable products.

Read more

See Schmitz Differently

For more than 35 years, the name Schmitz has been synonymous with XPE foam recycling. But now, it's time to expand your perspective. Because we are not just recycling experts, we are also XPE foam creators.

Read more