Schmitz Foam Recycling

Since 1990, we successfully give XPE foam residues a second life. Thanks to our recycling process our partners worldwide save elimination costs and avoid environmental damage. Together, we make sure that no foam goes to waste. Let us give your foam residues a purpose.

We are proud and this is why...

Years experience in foam recycling

Suppliers of high quality foam residues

Sea containers foam yearly saved from incineration

Ready to give your foam residues a second life

About Schmitz Foam Recycling

Our long-term partners value our expertise and proactive approach in finding customized solutions for continuously providing their XPE foam residues a purpose.

Our XPE foam suppliers can rely on us for taking care of their residual foam. We are proud to say we are one of world's largest processors of XPE foam residues with over 35 years of expertise.

We value long-term partnerships, in which we can offer our mutual and ideal solution. It is a 'total care service' including collection solutions and unique processing of XPE residues.

Cooperate with us

How our foam recycling process works

Contact us

Contact us to find out if your foam residues suit our recycling process.

We collect

Together we determine how, when and where to collect your foam waste efficiently.

Save costs

Save on elimination costs and prevent your foam residues from ending up in landfills or incinerators.

We recycle

We recycle your foam residues and give it a purpose. All of the reworked XPE foam is used in our high-end products.

Zero Foam Waste

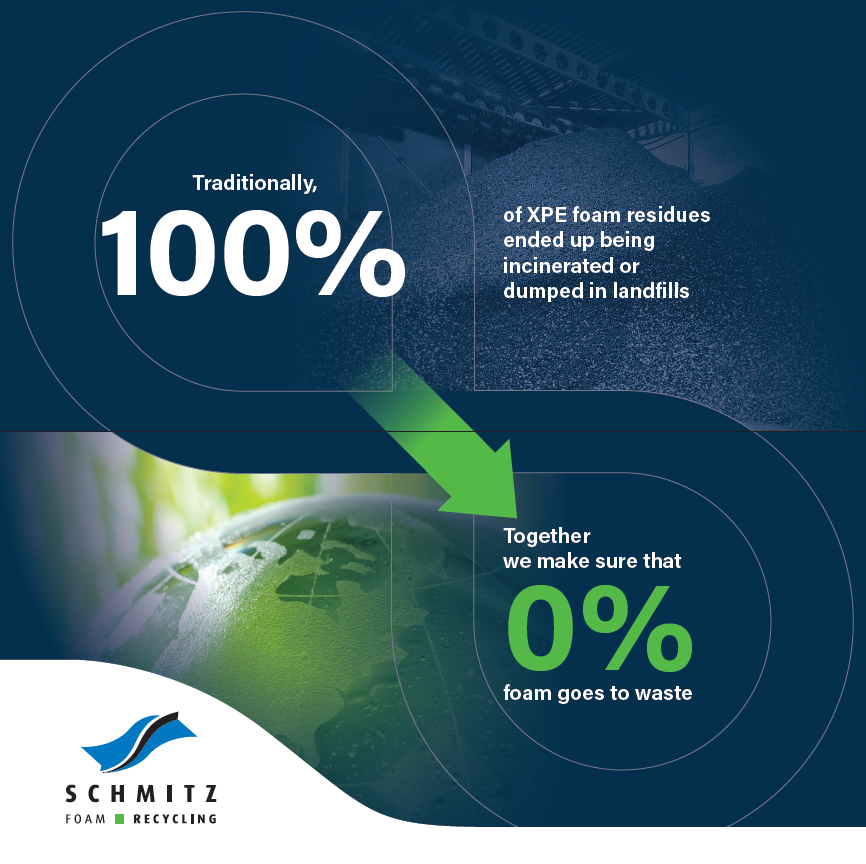

Traditionally 100% of XPE foam residues ended up being incinerated or dumped in landfills. Thanks to our foam recycling process our partners world wide avoid environmental damage.

Together we make sure that 0% foam goes to waste.

Have a look at the circular approach we employ when we collect foam residues. See how we transform foam scraps into a new raw material, which we then upcycle into high-quality and sustainable products that enhance sports fields and playgrounds. These products can be recycled again at the end of their life, thus completing the cycle.

Benefit from our recycling service!

Get in touch with us.

Schmitz Foam Recycling

Why not recycle for free! It's up to you.

Which solution suits you?

XPE foam is a high-volume product, making transportation costly. Since 1990, Schmitz has developed several unique methods to collect XPE foam residues efficiently and cost-effectively.

Which solution suits you best? That depends on material thickness, density, quantity, scrap dimensions and previous treatments. The distance to our factory is important too.

Please contact us, together we find out which solution works best for you.

Depending upon the quantity of XPE foam residues we offer several solutions:

Press bales

Shred the foam residues to flakes

Load the foam residues in bags

Load rolls

Shredder at your plant

In some cases, we can provide a shredder for your plant, making you part of the recycling process of your own residuals. We pick up the shredded foam and transport it to our own plant. In this way, transport costs are reduced significantly.

Contact us to find out what we can do for you

Are you wondering how we can process your XPE foam residues? The main commodities we use for our high-end products are closed cell cross-linked XPE and XPP foam. Depending on the quality, we can use other foam materials as well.