Since the late 1980s, Schmitz' dedication to innovation has driven us to develop top-performance shock and drainage solutions. ProPlay shock pads enable athletes and children to live a healthy lifestyle and to add great value to a safe artificial grass surface. That's why ProPlay is the perfect fit for your artificial turf system, both now and for years to come.

A shock pad

that has it all

ProPlay delivers the lasting performance you can expect from a well-established shock pad. Depending on its application the pad provides the right balance between a solid underfoot (vertical deformation), user comfort (shock absorption) and player safety (impact attenuation).

What makes the ProPlay shock and drainage pad really stand out is the fact that it offers the ultimate combination of all desired shock pad characteristics combined with superior drainage.

These characteristics make ProPlay truly unique through which it can add tremendous value to your artificial grass project.

Above average thickness and density

ProPlay is thicker and denser than other shock pads on the market. This combination is the reason that our durability exceeds that of other high-end shock pads.

Open structure /

water permeability

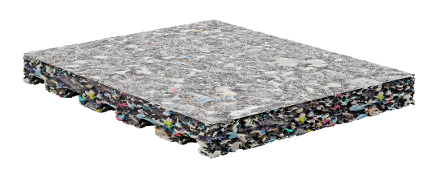

ProPlay is made of polyethylene foam layered on top of polyester textile. Our sophisticated production process generates a rigid sheet with an open structure. This provides water permeability and thus very good vertical drainage.

Additional horizontal drainage

In addition to the excellent vertical drainage, ProPlay can also be delivered with outstanding horizontal drainage properties. This allows you to achieve great savings in both time and cost as there is no need to replace the entire subbase and install a vertical drainage system.

Fall protection

Whether it’s applied beneath the artificial grass of a prestigious rugby field or underneath your local playground, ProPlay provides safety - our shock pad complies with the Head Injury Criteria required for specific sports fields and HIC certified playgrounds.

Insulating characteristics

Using ProPlay underneath artificial grass systems in regions that are more likely to experience regular or harsh wintry conditions, allows for a reduction in the thickness of the subbase. Its above average thickness and high thermal resistance mean less aggregate, resulting in much lower subbase costs.

Rigid, flat and stable

ProPlay provides a very rigid foundation to install your artificial grass on. This will complement a perfect ball bounce and roll for a flawless game experience.

Why we are the experts

ProPlay is used as a shock absorption and drainage pad in sports fields and as a fall protection pad in playgrounds in over 70 countries worldwide. Adding value to foam has been an important component of the history of Schmitz Foam Products. In the late 80s we started researching possible ways to re-use redundant foams to increase the safety and playability of artificial grass surfaces.

Over the years the process of adding value to these foams has been fine-tuned to stay ahead of developments in the artificial grass industry. Upscaling a product requires extensive knowledge about the material, well-defined production processes, stringent quality monitoring systems and dedication. Schmitz Foam Products is fully dedicated to producing top-performance shock and drainage pads.

All-in-one

The Schmitz company fully controls the entire process. From researching and selecting only the best foams to raw material acquisition. From constantly monitoring our production process to in-house testing of the sport technical performance. Everything “under one roof”…well, actually two: in Roermond (NL) and Coldwater (US).

Fully dedicated

Schmitz Foam Products is fully dedicated to producing top-performance shock and drainage pads to enable athletes and children to live a healthy lifestyle, and to add great value to a safe artificial grass surface.

Inhouse raw material sourcing

Schmitz Foam Products only works with the highest-grade foams and according to a well-controlled raw material management process. You can rest assured that the end products are always of a consistently high quality.

Well-controlled production

A stringent selection process ensures no material other than cross-linked PE foam makes it to our production facilities.

A sophisticated process is followed to define the right mixture to produce the ProPlay shock and drainage pad.

Measuring is knowing

For every 250m² produced, samples are tested for their physical characteristics, while the sport technical performance, including shock absorption, energy restitution, vertical deformation, Gmax/HIC and horizontal drainage (where applicable) are tested for every 1250m².

ISO 9001:2015 certified

The Schmitz Foam Products quality procedures and testing methods are audited annually. Since 2004 the company is ISO 9001 certified.

ESTC Performance Guide

for Shock Pads

Schmitz Foam Products was one of the driving forces behind the development of a set of international guidelines that value the performance of shock pads as part of an artificial grass system. Download here the ESTC Performance Guide.

ProPlay: the most sustainable shock pad available

All ProPlay products are made of quality foams that no longer have a meaningful purpose in their particular industries such as the automotive, packaging, sports and leisure and construction industries. By giving these foams a new purpose, Schmitz Foam Products prevents them from ending up in landfills or incinerators, which consequently reduces the need for fossil fuels for the production of virgin foam.

Once a ProPlay shock pad is no longer needed for its original application, the material can always be reused in another sports field or playground or returned to our plant and recycled into new pads for use in another purpose. Schmitz Foam Products also accepts shock pads from other producers for recycling purposes. Provided the shock pad is made from cross-linked polyethylene it can be offered to Schmitz Foam Products be recycled for another purpose.

Ask our experts

ProPlay shock pads have been installed in over 80 countries. We have the experience and can always assist you.