Consistent quality

Made from quality foam into a high performance shock pad

At Schmitz Foam Products we are committed to delivering top quality for both our shock and drainage pads and for our processes.

At Schmitz Foam Products we are committed to delivering top quality shock and drainage pads produced through advanced quality processes. Our commitment to use the highest quality materials and processes has allowed us to be an ISO 9001 certified company. To guarantee quality, all products are produced under our in-house manufacturing control and are constantly monitored during the production process. Add to this the fact that Schmitz Foam Products only works with the highest-grade foams and according to a well-controlled raw material management process and you can be assured that the end products are always of the most consistent and highest quality.

Choose ProPlay = prevent landfill

All ProPlay shock pads are produced from remnant foams that have passed all quality tests and are collected directly from foam manufacturers and converters. This includes foams produced during start-up or closing-down of the production process, cut-offs, and foams that no longer meet a need. Simply said these are brand new foams that were never used for their original purpose. If Schmitz Foam Products did not provide a meaningful purpose for these foam products by reprocessing them in to a world class shock and drainage pad, they likely would be disposed in a landfill or incinerated. These options are less than desirable in an environmentally conscious society.

Dedicated to only one thing!

ProPlay is used as a shock absorption and drainage pad in sports fields and as a fall protection pad in playgrounds in over 70 countries worldwide. Repurposing foam has always been an important part of the history of Schmitz Foam Products. In the late 80s we started to research possible ways to re-use remnant foams to increase the safety and playability of synthetic turf systems.

Over the years the process of adding value to these foams has been fine-tuned to stay ahead of developments in the synthetic turf industry. Remanufacturing a product requires extensive knowledge about the material, stringent quality monitoring systems, well-defined production processes and dedication. Schmitz Foam Products is fully dedicated to producing high performance shock and drainage pads enabling children and athletes to play and perform safely and add great value to a safe synthetic turf system.

Well-controlled production

Our foams are sourced from major foam producers and converters worldwide. The foam is subject to visual and mechanical inspection upon arrival at the Schmitz Foam Products plants. These inspections ensure that no item or material other than the cross-linked PE foam makes it to the ProPlay production facility. Once this has been established, the foam is shredded into flakes that are temporarily stored in a controlled environment. A sophisticated process is followed to define the right mixture and to layer the shredded foam on top of a polyester textile.

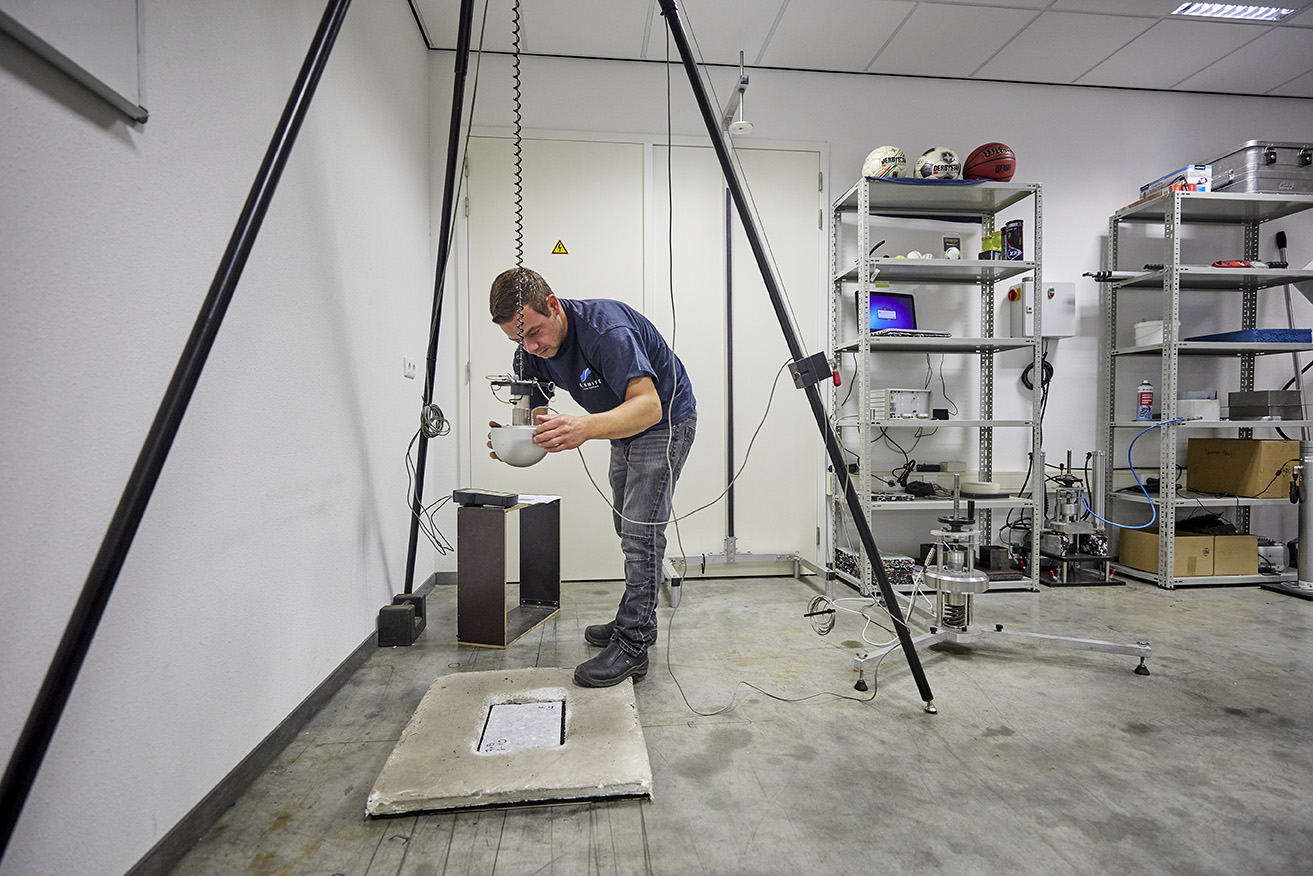

Measuring is knowing

Both Schmitz Foam Products plants have fully equipped laboratories to validate the quality of the ProPlay shock absorption and drainage pads:

ProPlay-Sport is tested on its physical

ProPlay-Sport is tested on its physical

characteristics on 30 random positions

ProPlay is tested

Samples are tested for their physical characteristics for every 2,500 sf of sheets produced. In addition, for every 12,500 sf of ProPlay produced the sport technical performance is assessed, including shock absorption, energy restitution, vertical deformation and Gmax/HIC.

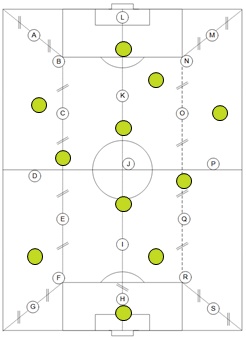

Tests that exceed regulations

As an example FIFA regulations dictate that testing companies quality-test an synthetic turf soccer field at 19 different locations. The regular quality inspections that we submit exceed that standard and are equivalent to a soccer field being tested at 30 different locations.

Everything in house to test

We have samples of most common infills and carpets available to allow us to test the performance of ProPlay in any system. The systems are subjected to all available tests to establish the performance and behavior of a field installed with a shock pad. This includes all relevant impact attenuation tests, like shock absorption, Gmax and HIC.

A good team

We cooperate with highly qualified independent testing laboratories to validate our internal test results.

%20Base.jpg)

Approved for use in synthetic turf systems by many turf producers

With a proven track record on synthetic turf sports fields and playgrounds featuring our shock pads worldwide, our ProPlay gets the ‘green light’ when it comes to tests in accredited laboratories. The same goes for the renowned worldwide sports governing bodies like MLB and the NFL. This proves that our product performs not only by itself but more importantly as an integral part of a synthetic turf system.

We care about the environment

At Schmitz Foam Products we care about our planet and environment. This goes beyond our production locations and employees. We are very proud that our products comply with the European REACH regulation and many other recognized environmental standars globally.

Environmental regulations depending on geographic location often require additional compliance to those included in the REACH regulation. With exporting our product to more than 70 countries worldwide, our shock-absorbing and drainage products are tested for those additional demands.

A frequently requested requirement for synthetic turf surfaces for outdoor sports is the toxicology protocol established by the Synthetic Turf Council (STC). Conformity to this standard is mandatory for outdoor sports surfaces in North America, with the same or similar requirements needed in many other countries worldwide.

Environment, health and safety credentials

Cross-linked polyolefins are chemically stable by nature. Any compounds contained in the material will not be released during the lifetime of the product. ProPlay can be safely used for any artificial grass system. The products do not leach chemicals that pose a risk for the environment and/or human health.

ProPlay-Sport complies with:

- STC Performance and Durability Guidelines for Shock Pads:

This guideline provides evaluation criteria for end users and designers while assisting shock pad manufacturers in their Quality Assurance programs. - STC Toxicology Analysis:

ProPlay passes the STC Toxicology Analysis on all components. In case you need more info on this, feel free to contact us. - The state of California’s Code of Regulations (CCR):

- Title 22 ‘Social Security’ Div. 4.5

‘Environmental Health Standards for the Management of Hazardous Waste’.

- Title 27 ‘Environmental Protection’ Div. 4

‘Office of Environmental Health Hazard Assesment’ - Chapter 1 ‘Safe Drinking Water and Toxic Enforcement Act of 1986’ (Proposition 65).

Need more info or specific test reports?

Schmitz Foam Products is proud to be able to produce this high performance shock absorption and drainage pad in accordance with these prominent national and international standards. If the quality standard you need is not on the above list, or if you would like to receive more information or specific test reports...

The Schmitz Foam Products quality procedures and testing methods are audited annually. Since 2004 the company is ISO 9001 certified. Also our manufacturing plant in Colwater (MI) is ISO9001 certified to ensure consistent quality.

The Schmitz Foam Products quality procedures and testing methods are audited annually. Since 2004 the company is ISO 9001 certified. Also our manufacturing plant in Colwater (MI) is ISO9001 certified to ensure consistent quality.