A safety and comfort layer that keeps even the youngest children safe

Maintaining and improving the relationship with its distributors is as important to Schmitz Foam Products as those relationships children foster when playing on a playground fitted with a ProPlay shock pad.

ProPlay shock pads are being used in sports fields and playgrounds in over a third of the countries around the world. “Sports fields are vast and straightforward, whereas playgrounds and landscaping projects are smaller in size, and the design and layout are often more complicated,” says Jens Ulb, the Chief Commercial Officer at Schmitz Foam Products. “As we are well aware that the final output is determined by the quality of our input, we strive to work together with established and experienced companies to take installations to a higher level.” The fully equipped laboratory of Schmitz Foam Products is just one example of how partners are supported. “Here we can test to see if a particular artificial turf carpet on a ProPlay shock pad will comply with the requirements dictated by DIN 1177, the internationally accepted standard for impact attenuating playgrounds. The results can help distributors and partners to predict the best possible solution for a playground.”

Constant quality

Artificial turf is the surface of choice for many to finish today’s modern playgrounds. “Artificial turf is more stylish and aesthetically appealing. It requires hardly any maintenance to ensure the performance is maintained, while its resemblance to grass delivers a playing surface everybody can relate to. An artificial turf surface can also handle much more footfall compared to the traditional grass or gravel surfaces. Furthermore, their excellent draining properties mean that the surface no longer becomes muddy during or after heavy rainfall,” Ulb continues.

Where the quality of in-situ surfaces relies more on the experience of the installation crew and weather conditions during the installation, the quality and performance of ProPlay panels as part of an artificial turf field is constant. The panels are produced according to a strict production protocol, whereby production procedures and conditions have been well-defined and are always adhered to. It doesn’t matter what time of the day or where in the week a ProPlay panel is produced, the installer always knows the quality and performance he will receive.

Contributing to the partnership

Using ProPlay gives installers a strategic advantage. “Municipalities value the contributions ProPlay makes to the circular economy and in saving the environment. ProPlay is produced from remnant foams that no longer have a purpose. Because ProPlay is made of material that is prevented from going to landfill, it is often granted extra points in tender processes where sustainability is valued,” Ulb points out. Furthermore, partners can return reclaimed ProPlay or other closed-cell polyethylene shock pads to Schmitz Foam Products. “Once they have cleaned and packed the reclaimed material according to the guidance we have provided, they can ship it to our plant in Roermond, the Netherlands or Coldwater in the US. Here, they will be inspected, and, once approved, converted to raw materials that we use for producing foam products for other purposes.

Partners and installers also benefit from the unique puzzle-shape of ProPlay. “The dimensional strength and its unique shape means that ProPlay is easy to handle and contributes to a speedy installation,” Ulb remarks. The panels can easily be cut to size and connected to ProPlay panels that have already been installed. “The final result is a stable and flat surface which will contribute to the experience children will have while playing around.”

All purposes covered

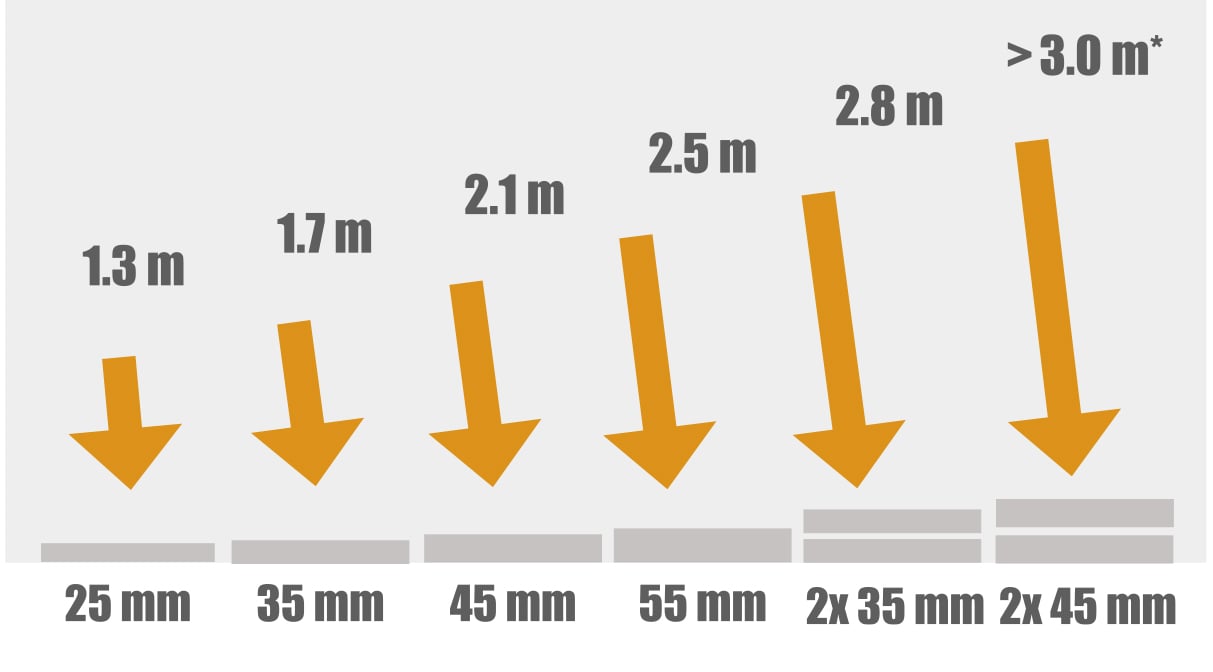

The Schmitz Foam Products portfolio for playgrounds hands partners several options. “The thickness of ProPlay for Playgrounds varies from 25 to 55 mm. This enables the installer to meet the various HIC values determined to provide a safe playground.” ProPlay for Playgrounds differs slightly from the ProPlay solutions Schmitz Foam Products offers for multi-game courts and sports grounds. “Where a shock pad for playgrounds has to provide safety, cushioning and comfort, a shock pad for sports or multi-game fields also has to provide stability, as well as the ability to run comfortably. For that reason, bigger, thicker and more light-weight foam flakes are used for producing ProPlay for Playgrounds, compared to producing ProPlay for other applications.” The mixture of the flakes, which are thermally bound on a non-woven backing, results in bigger voids between the foam flakes. “As we use only closed-cell polyethylene foam, this means that the water drains through the shock pad very quickly, into the subbase underneath. ProPlay doesn’t absorb water, hence it can be used in areas that experience heavy rainfall or temperature fluctuations.

The Schmitz Foam Products ProPlay for Playgrounds portfolio has safety and comfort layers to comply with every HIC value.

The Schmitz Foam Products ProPlay for Playgrounds portfolio has safety and comfort layers to comply with every HIC value.

While Schmitz Foam Products continually reviews its products and researches possible improvements, the ProPlay for Playgrounds portfolio hasn’t really experienced major changes or replacements over the years. “We actually offer a standard range of fall protection products, which guarantees our partners stability, as they know exactly what it is that they will get and how it will perform. They also know that the 10-year warranty we offer on our playground products is based on real-time experience.” Jens Ulb is clear about the aims and performance of both ProPlay and Schmitz Foam Products. “Our ProPlay products offer comfort and stability for playgrounds the Schmitz Foam Products organisation strives to provide comfort and stability to our partners,” he concludes.